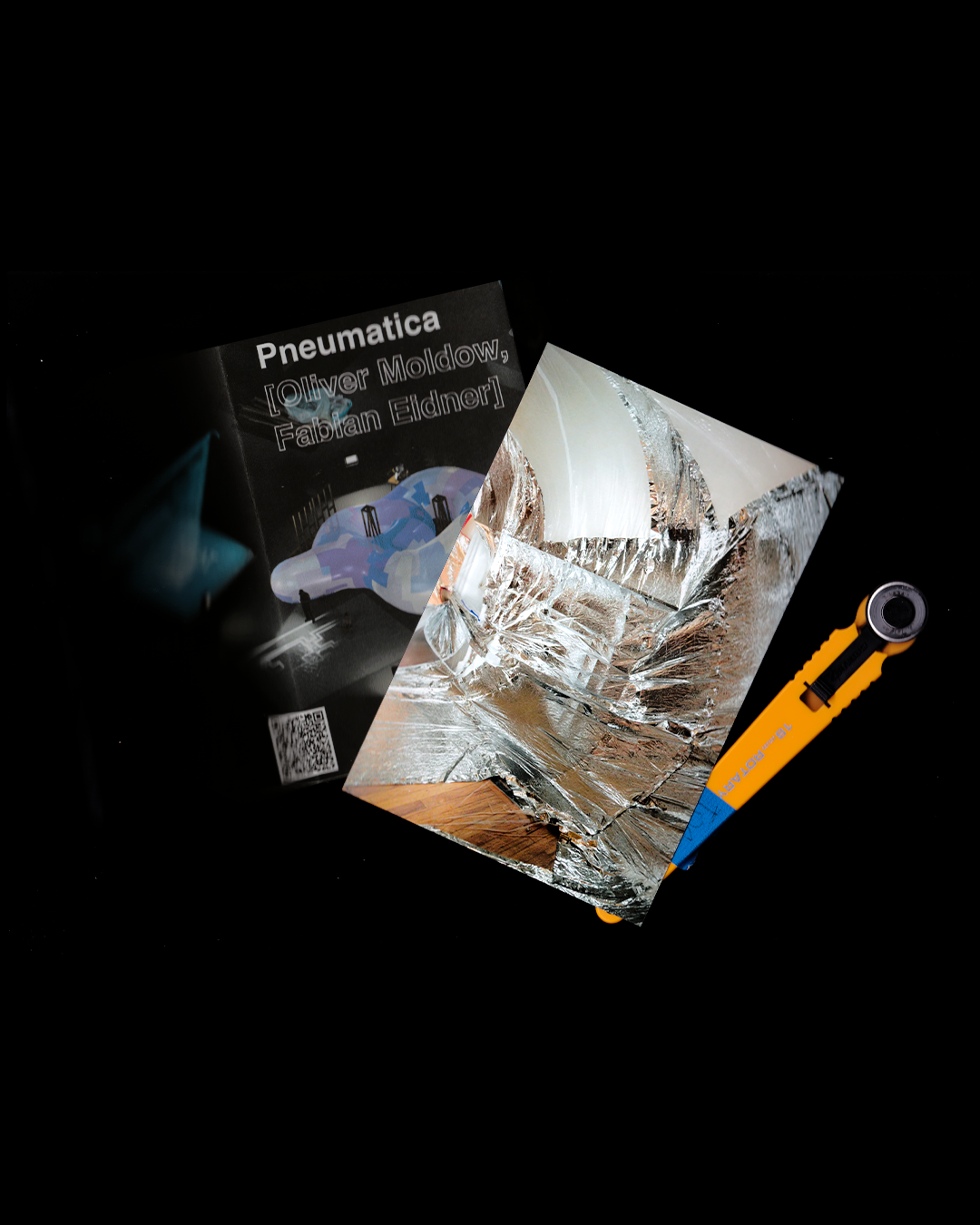

Snip Snip: Ad Hoc Pneumatic Space Making

Oliver Moldow MSc & Fabian Eidner MSc

Introduction

In an era defined by energy scarcity, an excess of single-use plastic, and abundant environmentally-irresponsible building stock, there must be radical new design and fabrication methods that merge the architect, engineer, and user. Insulated, they are not equipped to tackle the modern building industry and its landscape of homogenous and monolithic structures that cannot satisfy the multiple and contrasting needs of their inhabitants: leaky windows, rectilinear forms, non-shape optimized construction. This research thesis explores environmental post-construction at the tenant level with ad-hoc pneumatics, circumnavigating industrial construction paradigms by leveraging household tools, user excitement, and low-tolerance fabrication.

Reconditioning/Rehabilitate Space

Nearly 70 years ago, Reiner Banham argued for gradient building thresholds in his seminal works “The Architecture of the Well-Tempered Environment,” and “Monumental Windbags.” He suggested that building envelopes with thermal gradients have less heat loss and lower energy loads. We argue that these differentiated threshold conditions—both spatially and climatically—can be achieved with temporal intervention using inflatable systems, linking the performative capacity of their material system with environmental modulation. Hence, there is a possibility for alternative spatial strategies and morphologies by deploying functionally graded conditions within existing ruled building frameworks.

Fabrication

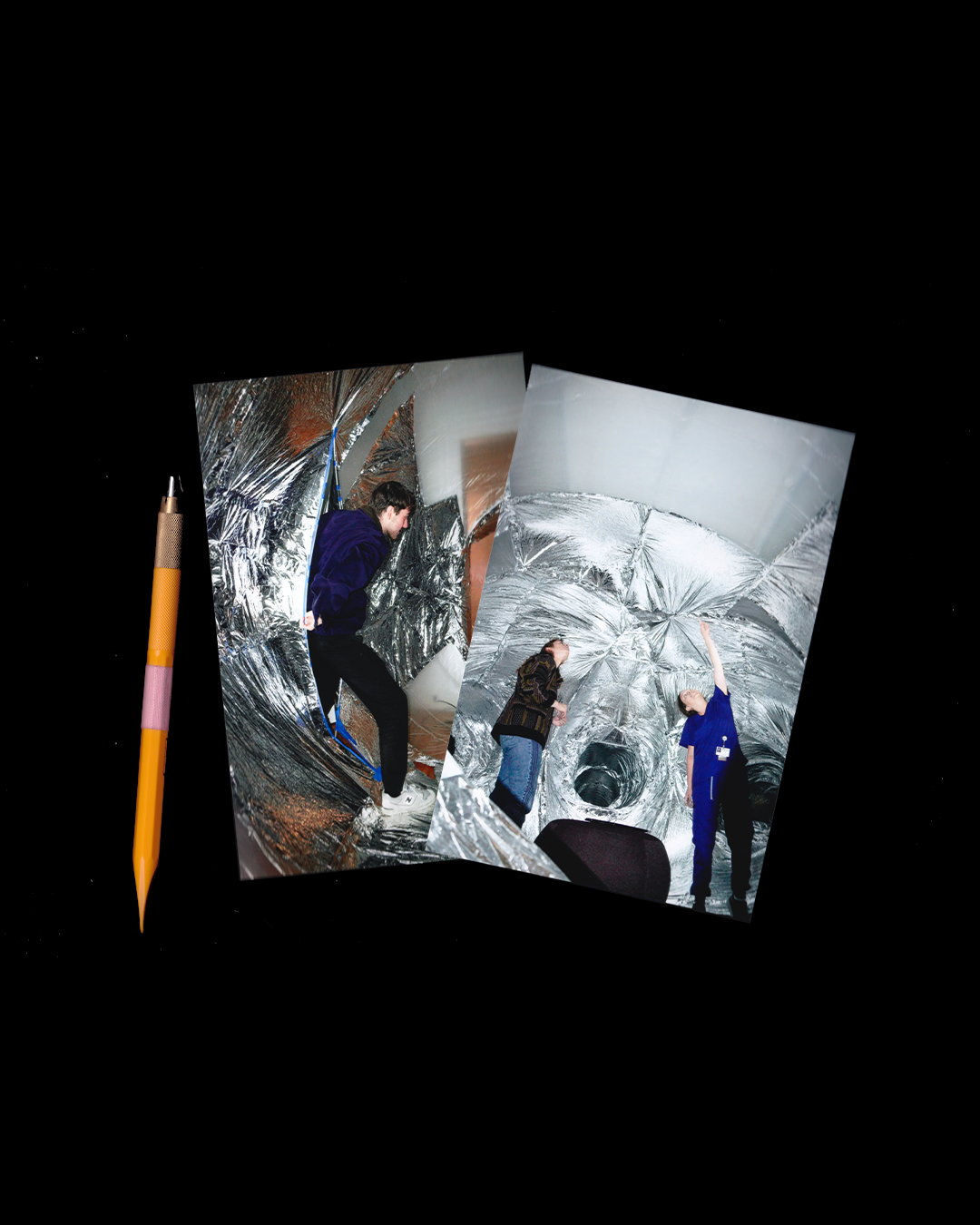

We suggest that all design explorations that acknowledge existing context should happen in-situ. As such, the modeling processes for this research utilized accessible technologies and had fabrication novices in mind. Portable tools—smartphones, scissors, tape, and cheap off the shelf materials like mylar and painter’s tarp—made for rapid ad-hoc production of low-pressure inflatables. An augmented reality app guided users through the modeling process and provided real-time fabrication instructions using a custom patterning algorithm designed to minimize material offcut. These novel fabrication techniques were tested in a two-day workshop, where students used AR modeling, patterning, and fabrication to create a 150m2 (≈1615ft2) full-scale demonstration with only ~3kg of material.

Occupation/Perspective/Outlook

The inflatable demonstrator debuted at the Harvard GSD Kirkland Gallery, serving as a temporary gathering space revitalizing three formerly-vacant rooms. Within a week of its construction, the structure was packed into a single suitcase, and re-deployed at the University of Stuttgart as an exhibition space–turning out the contents of 40 Kirkland Street and conforming to its new spatial conditions halfway across the globe at Keplerstrasse 11.

The processes developed in this project exemplify user-oriented tool development and allow for the inclusion of non-experts in retrofitting their own spaces. In a broader context, we showcase how emancipatory approaches may extend beyond current pedagogy and, in turn, expose new avenues for bottom-up participation in our built environment.